Strive for excellence - 2018 Lean Production Stair Training - Lean blue belt training class

A professional team with professional knowledge and practical experience needs to be built by Shuanglin through combining with the strategic planning of lean production personnel training, so as to support lean work, deepen lean management and create lean culture.

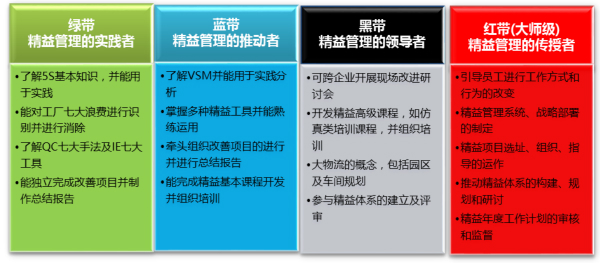

According to the level of ability, members of this professional team can be divided into four levels: lean green belt, lean blue belt, lean black belt and lean red belt. Each level shall pass the internal qualification assessment in accordance with the Assessment Standard for Lean Production Personnel Qualification and obtain the qualification approval before being granted the corresponding letter of appointment.

On this basis, the training and qualification assessment of lean production personnel will be officially kicked off in 2018, initiated by the enterprise management center and under the joint efforts of enterprise, universities and various business divisions.

Lean Production Stair Training - Lean blue belt training class, as one of the important links, is first presented.

On August 11, Lean Production Stair Training - Lean blue belt training class of Shuanglin Group was grandly launched in Ninghai Tianmingshan Forest Hot Spring Hotel. Through the training to the four business divisions and the plant lean enablers, the training class enables the lean enablers at all levels to have preliminary lean thinking and master lean tools, so as to achieve the goal of eliminating waste and shortening the production cycle, and quickly adapt to changes in user demands.

Cheng Jixiang, director of the President's office, attended at the opening ceremony and delivered a speech. His speech emphasized that lean manufacturing is influencing the entire manufacturing industry, especially the automobiles industry, with its unique advantages. More lean talents are required by Shuanglin for improving manufacturing ability with professional knowledge and methods. At the same time, Shuanglin has started the qualification identification project for lean production personnel. The 4-day training is the key link of this project and each trainee should grasp the rare opportunity to acquire more lean knowledge.

Factory Lean Logistics and Error Prevention Technology are included in the training courses.

Factory Lean Logistics directly illustrates the essence of lean, i.e. shortening production cycle and accelerating capital turnover. For this purpose, it is necessary to systematically sort out the three flows of the factory, i.e. logistics, information flow and process flow. Moreover, the appropriate lean tools - balanced production scheduling & pull production are used to realize lean operation of factory logistics and reduce inventory based on clear lean organization structure and reasonable target.

Error Prevention Technology enables the students to understand the producing process, mechanism and error prevention mechanism of defects from the conventional principles, and presents a new appearance by providing the knowledge and skills on error prevention principles in the training class.

The two trainers have rich experience in teaching, and the ability to combine theory with practice in the teaching process. The lectures are lively and interesting, and the classroom atmosphere is very active.

Mr. Liu, the trainer of Factory Lean Logistics, introduced the lean production concept from the evolution of the manufacturing industry, guided the lean improvement system through the inventory demand relationship, and analyzed the lean production tools in the production process from three series of information flow, process flow and logistics, which enabled the students to have a new understanding of the lean logistics in the factory. Mr. Du, the trainer of Error Prevention Technology introduced the concept of "Poka-Yoke" to help trainees first understand the basic principles of error prevention technology, and then understand how the error prevention technology was applied to practical work through the successful case analysis of safety, quality, efficiency, equipment and cost.

All 38 trainees participated in the four-day training. During the training, the trainees shared their production status in interactions, and the trainers constantly enhanced their understanding and practical abilities through case explanation and analysis. The extremely high practical value of the course benefited everyone a lot.

On August 14, the training course was successfully concluded, and the trainees gave their unanimous praise to the four-day training course. For example, Zhou Yang, from the Auto Accessories Division, said that: through learning courses, I realized that there is much room for improvement in the form of daily production material transportation in the factory. I will transfer the learning content of the training and apply it to practical work. Zhang Zhiyang from the Power Assembly Division expresses: the error prevention courses enables me to learn the methods of error prevention that I have never been exposed to before, which is very practical and helpful to factory production.

"Profound knowledge lays a solid foundation for rising abruptly", the training intensifies the lean production concept of the trainees, to better encourage all business divisions and factories of Shuanglin to keep improving and pursue excellence.